APPLICATIONS: Other Industries

LaserGauge® can be used in any industry that requires quality control measurements of gaps, paint thickness, corrosion, engraving, welds, and more.

LaserGauge® products have been used for the following industry applications:

- Welding on wind turbine towers

- Scratches on medical devices

- Gaps on household appliances and office equipment

APPLICATIONS & RECOMMENDED SENSORS

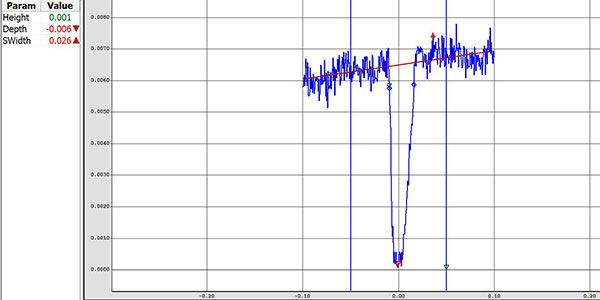

There are several types of etching and engraving. Chemical, laser and stamping are the most common and can be utilized on a variety of materials and finishes available, ranging from mirror finished stainless steel to aged and distressed brass. Chemical and laser are non-contact processes. Chemical typically leaves a burr free finish but residue, slag and contaminants may compromise the results. Laser systems can cause heat distortion of the material. Stamps may become worn over time and lessen the quality of the finished product. All need to be inspected over time and evaluated for integrity.

The quality and permanency of etched or engraved metal make it an ideal solution for many applications including logos, VIN or part numbers, signs and other identifiers.

Recommended Sensors

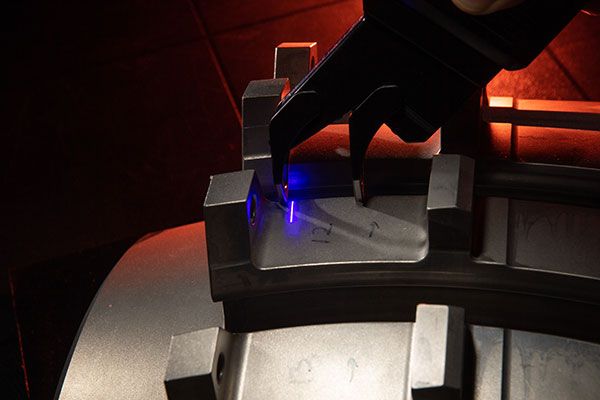

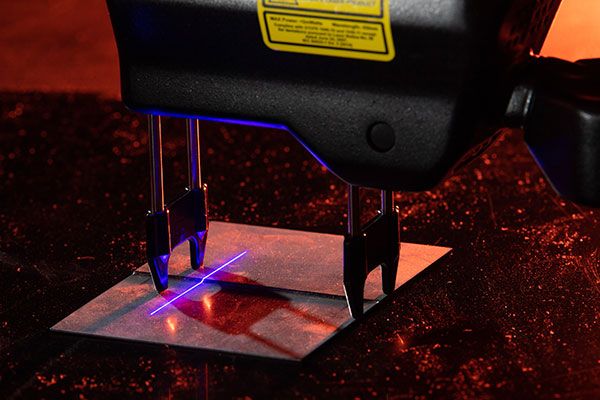

TS800 USB SENSOR WITH RED OR BLUE LASER SINGLE STRIPE TECHNOLOGY

OPTIONAL LG7000 CONTROLLER

Scratches, Gouges, & Dents

Scratches and gouges on tubes, pipes and other surfaces must be measured to determine how much material has been removed, and thus, how much of the original surface or wall is remaining. Depth micrometers and other mechanical devices cannot provide meaningful measurements because of the contour of the surfaces and the small features that have to be measured. Thresholds for the amount of material that can be missing are in the thousandths of an inch, so the measurement instrument must achieve this resolution.

Download Application Datasheets

Download Case Study

Recommended Sensors

TS800 USB Sensor

Optional LG7000 Controller

Pitting & Corrosion

Download Application Datasheet

Recommended Sensors

TS800 USB SENSOR WITH RED OR BLUE LASER SINGLE STRIPE TECHNOLOGY

OPTIONAL LG7000 CONTROLLER

Contour

Residential siding board has a wavy pattern on the front side. The production process must ensure that the contour of those waves consistently stays within a range. If the profile of the boards is not consistent, they will appear to be different colors when installed on the side of house and the consumer will not accept this patterned look.

There are no mechanical tools that quickly and easily analyze the contour. Tracing the contour with a stylus and then printing out the profile for comparison is too time-consuming. And other optical and visual methods are not reliable.

Download Application Datasheet

Recommended Sensors

HS702 OR HS703 DSP SENSORS WITH RED OR BLUE LASER SINGLE STRIPE TECHNOLOGY

TS800 USB SENSOR WITH RED OR BLUE LASER SINGLE STRIPE TECHNOLOGY

OPTIONAL LG7000 CONTROLLER

Welds

Inspection of welds can be performed on a sampling basis after the welding process is complete. Inspection includes measuring the height difference of the two panels on either side of the weld and analyzing the profile of the weld for concavity and convexity. These measurements cannot be made with any mechanical tools and cannot be performed by operators visually.

A straddle standoff accessory is necessary for this type of measurement. This standoff comes standard with the TS800 sensor but is a separate accessory for the HS703 and HS703 sensors.