APPLICATIONS: Assembly Line Fit-Gate

The LaserGauge® Fit-Gate solution for automotive assembly lines has been installed in dozens of automotive plants around the world.

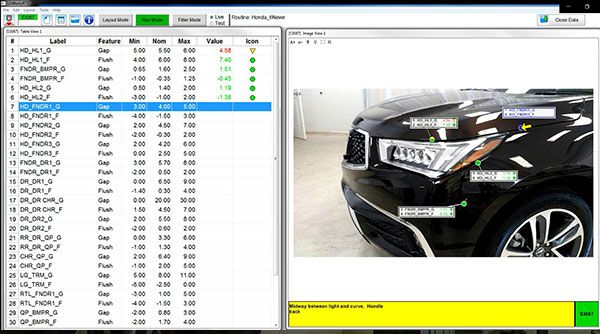

The LaserGauge® Fit-Gate System is a multiple-sensor inspection configuration using one or two LaserGauge® DSP sensors for 100% inline inspection of closure gap and flush in automotive plants. The Fit-Gate is used in both body-in-white and final assembly applications. Single-location gap and flush measurements as well as cross-car, V-gap and A-gap calculations are acquired. Each location can be measured in approximately one second per point.

Data from the Fit-Gate System can be saved locally, to a networked drive, or sent to a plant data handling and SPC system via serial or Ethernet interface.

LaserGauge® Fit-Gate Features

- Uses 2 DSP sensors to measure on both sides of car

- Automatically loads correct inspection routine based on VIN of car. Can receive the VIN from:

- Independent barcode scanner

- Optional barcode scanner on HS702 and HS703 sensors (Standard on HS761 and HS763)

- Manual entry

- Factory (PLC, Ethernet, Serial)

- In- and Out-of-spec conditions automatically calculated and notated. Other calculations, such as cross-car, A-gap, V-gap, max/min are made automatically.

- Inspection status displayed on monitors viewable by inspector, showing in- and out-of-spec locations and values or by audible tone to indicate measurement status

- Data automatically saved locally or on network drive

How the LaserGauge® Fit-Gate Works

- PC runs LGWorks routine

- Sends sensor setup information to sensors

- Receives inspection data from sensors and compares to spec limits

- Displays inspection data in color-coded format to large monitor viewable by inspectors and sounds an audible tone to indicate in- or out-of-spec measurements.

- Saves data to user-defined data format for factory storage and use, even in multiple locations

- Sends inspection data to optional Fitter’s Station for final correction of out-of-spec features

- Can print inspection summary to printer

Benefits of using the Laserguage® Fit-Gate

- Repeatable – multiple operators, all locations, all variations of models, colors, trim packages

- Flexible – large amount of measurement configurations and number of gauges

- Traceable – useful to track by model, plant, shift, etc for quality management

- Stable – fixed calibration with many installations

- Fast – meets data rate requirements