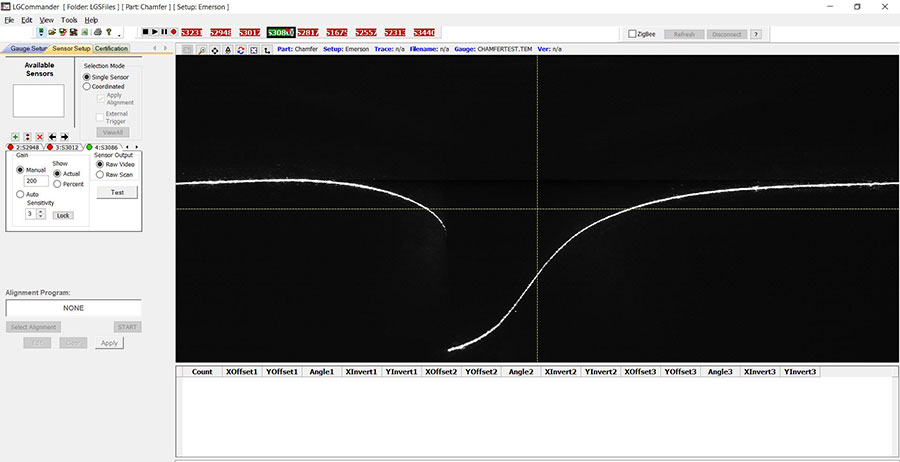

Raw Video

The Raw Video test mode allows you to view the sensor signal and determine the optimum manual setting. The image of the laser will appear in the video box.

This image helps to analyze possible surface reflections, incorrect gain settings, positioning of the sensor and other manual settings. These are all items that can affect the success of accurate measurements.

On-Screen Measurements

For some profiles there might not be a virtual gauge that will work, or one that returns the measurements desired. An operator can manually measure a feature on any captured profile by using the on-screen distance measurement tool. The operator can simply select the first point or edge in the scan by left-clicking and dragging the cursor to the other point or edge and releasing the mouse. The x,y coordinates will be used to calculate the delta x, the delta y, and the absolute distance between the two selected points.